I think custom kitchen cabinets are a great investment—but only if you do it right, the first time. Whether you’re renovating your forever home or boosting your home’s resale value,...

Outdoor Wood

By Mike Holmes

Mike’s Advice / Outdoor Renovations

Saturday, June 16th, 2018 @ 12:41am

When it comes to materials for outdoor wood projects, the 3 big contenders are:

- Pressure-treated or PT lumber

- Cedar

- Composite wood

1. Pressure-Treated (PT) Lumber

Pressure-treated lumber is wood that’s been treated with chemicals to make it resistant to rot and insects. It is strictly an exterior product. You cannot use it indoors and it should never be burned because of the chemicals it contains.

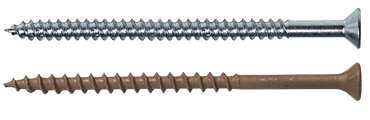

Years ago arsenic was used to treat PT wood and make it weather-resistant, but that was replaced with copper. The problem is that when PT wood gets wet the copper in it will start to corrode metal fasteners, including nails, screws and deck hangers. For this reason, special fasteners are required when working with PT wood.

You also need to be careful if your project requires flashing. Most flashing is aluminum, and exposed aluminum will corrode if it comes into contact with moisture, especially wet PT wood. Regular galvanized nails and screws won’t hold up for long either. You’ll start to notice staining around the screws and hangers, but eventually, they’ll corrode completely, which could lead to complete structural failure with devastating results.

The Right Fastener: Stainless steel or “green”

Stainless steel fasteners will not corrode but they are expensive, which doesn’t make them practical for homeowners on a tight budget. If money isn’t an issue your best bet is to use stainless steel fasteners, but a close second (and a less expensive alternative) are vinyl-coated “green” wood/deck screws. These are resistant to the chemicals in PT wood and some even have lifetime guarantees.

Maintenance

PT requires regular maintenance, which includes sanding, sealing and painting or staining at least every 2 years. Staining PT lumber rather than painting it could save you an extra year in between refinishing, stretching out the maintenance to every 3 years – as a bare minimum – but if you’re looking for longevity with little to no maintenance consider another material.

2. Cedar

- It looks and smells great

- It does not warp when exposed to moisture, which is an asset for exterior projects regularly exposed to precipitation;

- It’s naturally resistant to rot and insect damage, which means no dangerous, corrosive chemicals or off gassing;

- It requires less maintenance than other types of wood, like pine or spruce – even PT lumber.

- It doesn’t need to be treated with preservatives, unless it comes into direct contact with the ground, which it shouldn’t if your structure is properly built – you never want wood touching soil!

- It’s resistant to temperature-related stresses, which makes it good for environments where temperature changes and splitting are common.

Mike’s Trick of the Trade

Cedar has one big drawback: it’s expensive. If you like the look of cedar but you can’t take the cost, one way to save some money is to build your structure and support out of PT wood and use cedar for railings and decking. This will give you the look and smell of cedar, and some added strength and support.

The Right Fastener: Stainless steel or “brown”

Stainless steel is king, but again, it might be beyond most homeowners’ budgets. A great, and less expensive alternative is zinc-dipped or ceramic-coated “brown” wood/deck screws. The coating stops the screw or fastener from corroding, which prevents discolouration on the wood.

Buyer Beware?

If you think all cedar is created equal, think again. Cedar lumber from decades ago tends to be stronger and more durable than the cedar being harvested today because demand is driving millworkers to process cedar lumber earlier, before it’s been given enough time to mature and reach a certain standard in strength. Do your due diligence and ask about the product’s durability and strength. Just because it’s cedar doesn’t mean it’s good.

Maintenance

Exterior structures made from cedar should be cleaned it at least once a year with a mild detergent and water. If it requires restaining, a pressure washer can be used to remove old product but with extreme care and on a light setting. Cedar is soft and a pressure washer can damage it.

Cedar doesn’t necessarily need to be stained; it weathers to a grey-looking colour. But to protect it and keep it looking like new it will need to be stained. If you decide to stain cedar it will need to re-stained; usually at least once every 2 years.

3. Composite Wood

It can be textured to look like real wood, and different types are resistant to UV, fading, stains, insects, splitting and/or warping. But it will cost you – up to 5 times more than PT wood and in most cases, it’s even more expensive than cedar. What’s the benefit? Less maintenance.

Managing Expectations

Composite wood will fade, too. Because it is a manufactured product people expect it to look exactly the same as it did the first day it was installed. But like most things, composite wood fades when exposed to the elements and especially sunlight. PT lumber and cedar will fade as well – even more so than composite—but people tend to be harder on composite wood because it is a manufactured product.

The Right Fastener: Case-by-case basis

Composite wood is a manufactured product, and like most manufactured products, each different type requires it’s own set of specific installation practices, including fasteners. Most composite wood manufacturers will either recommend certain fasteners or provide their own with their product.

Mike’s Trick of the Trade

If you’re building a deck most contractors will tell you that the joists need to be 16 inches on centre, but 12 inches is better to prevent warping and dipping, especially when it comes to composite wood.

Maintenance

Composite wood does not require much maintenance. It should be washed or power washed at least once a year. Some manufacturers might recommend a cleaner or detergent. No matter what, always follow the manufacturer’s instructions on proper maintenance and upkeep.